1. Tlhokomelo ea valve ea heke

1.1 Lintlha tse ka sehloohong tsa tekheniki:

DN: NPS1”~ NPS28”

PN: CL150~CL2500

Lisebelisoa tsa likarolo tse kholo: ASTM A216 WCB

Stem-ASTM A276 410;Setulo—ASTM A276 410;

Sefahleho se tiisang—VTION

1.2 Likhoutu le Maemo a sebetsang: API 6A、API 6D

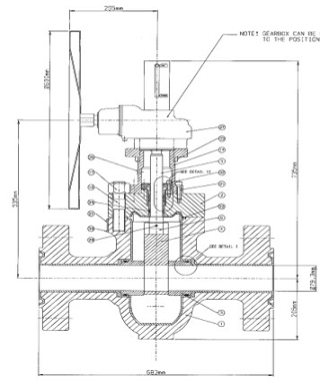

1.3 Sebopeho sa valve (sheba setšoantšo sa 1)

Setšoantšo sa 1 valve ea heke

2. Tlhahlobo le tlhokomelo

2.1:Tlhahlobo ea bokantle ba kantle:

Hlahloba bokantle ba valve ho hlahloba hore na ho na le ts'enyehelo, ebe u bala linomoro;Etsa tlaleho.

2.2 Hlahloba khetla le ho tiisa:

Sheba hore na ho na le boemo ba ho lutla 'me u etse tlaleho ea tlhahlobo.

3. Ho qhaqhoa ha Valofo

Li-valve li tlameha ho koaloa pele li qhaqha le ho lokolla liboutu tse hokelang.O tla khetha sepaneli se nepahetseng se sa fetoheng ho liboutu tse lokolohang,Manate a tla senngoa habonolo ke sepaneli se feto-fetohang.

Liboutu tse mafome le linate li tlameha ho kolobisoa ka parafine kapa se tlosang mafome;Sheba tataiso ea khoele ea screw ebe u sotha butle.Likarolo tse arotsoeng li tlameha ho baloa, ho tšoauoa le ho bolokoa ka tatellano.Stem le heke disc li tlameha ho kenngoa ka har'a bracket ho qoba ho Scratch.

3.1 Ho hloekisa

Etsa bonnete ba hore likarolo tse ling li hloekisoa ha bonolo ka borashe ka Kerosene, peterole, kapa lintho tse hloekisang.

Ka mor'a ho hloekisa, etsa bonnete ba hore likarolo tse setseng ha li na mafura le mafome.

3.2 Tlhahlobo ea likarolo tse ling.

Hlahloba likarolo tsohle tse setseng 'me u etse rekoto.

Etsa moralo o loketseng oa tlhokomelo ho latela sephetho sa tlhahlobo.

4. Ho lokisa likarolo tse setseng

Lokisa likarolo tse setseng ho latela sephetho sa tlhahlobo le moralo oa tlhokomelo;nka sebaka sa likarolo tse setseng ka lisebelisoa tse tšoanang ha ho hlokahala.

4.1 Tokiso ea heke:

① Tokiso ea T-slot: Welding e ka sebelisoa ho lokisa fracture ea T-slot, tšitiso e nepahetseng ea T-slot, Weld mahlakore ka bobeli ka bar e matlafatsang.Ho tjheseletsa ka holim'a metsi ho ka sebelisoa ho lokisa T-slot tlase.Ka ho sebelisa phekolo ea mocheso ka mor'a ho cheselletsa e le ho felisa khatello ea kelello ebe u sebelisa ho kenella ha PT ho hlahloba.

②Ho lokisa thepa e theohileng:

Ho theola ho bolela lekhalo kapa karohano e tebileng lipakeng tsa sefahleho se koalang heke le sefahleho sa Seat.Haeba belofo e ts'oanang ea heke e theohile, e ka tjheseletsa wedge e kaholimo le e tlase, ebe e sebetsa ho sila.

4.2 Tokiso ea sefahleho se tiisitsoeng

Lebaka le ka sehloohong la ho lutla ha valve ka hare ke ho koala tšenyo ea sefahleho.Haeba ts'enyo e le mpe haholo, ho hlokahala hore u chesehele, ho sebetsa ka machining le ho sila sefahleho sa ho tiisa.Haeba e se e tebileng, ho sila feela.Ho sila ke mokhoa o ka sehloohong.

a.Molao-motheo oa ho sila:

Kopanya holim'a sesebelisoa sa ho sila hammoho le workpiece.Eketsa abrasive ka har'a lekhalo pakeng tsa bokaholimo, ebe u tsamaisa sesebelisoa sa ho sila ho sila.

b.Ho sila sefahleho sa ho tiisa heke:

Mokhoa oa ho sila: ts'ebetso ea mokhoa oa matsoho

Smear abrasive holim'a poleiti ka mokhoa o ts'oanang, beha mosebetsi holim'a poleiti, ebe u potoloha ha u ntse u sila ka ho otloloha kapa "8" mola.

4.3 Tokiso ea kutu

a.Haeba mongoaha ofe kapa ofe sefahlehong se tiisitsoeng sa kutu kapa bokaholimo bo makukuno bo sa lumellane le maemo a moralo, sefahleho se koalang se tla lokisoa.Mekhoa ea ho lokisa: ho sila ka sephara, ho sila ka selikalikoe, ho sila ka gauze, ho sila ka mochine le ho sila ka Cone;

b.Haeba kutu ea valve e kobehile > 3%, ts'ebetso ea ho otlolla kalafo ka mochini o fokolang oa ho sila ho etsa bonnete ba hore bokaholimo bo felile le ho lemoha lepetso.Mekhoa ea ho otlolla: Ho otlolla khatello e tsitsitseng, ho otlolla ho batang le ho otlolla mocheso.

c.Ho lokisa hlooho ea stem

Hlooho ea kutu e bolela likarolo tsa kutu (sphere, kutu, top wedge, trough e kopanyang joalo-joalo) e kopantsoeng le likarolo tse bulehileng le tse koaletsoeng.Mekhoa ea ho lokisa: ho itšeha, ho cheselletsa, ho kenya lesale, ho kenya polaka joalo-joalo.

d.Haeba e sa fihlelle tlhoko ea tlhahlobo, e tlameha ho hlahisa hape ka thepa e tšoanang.

4.4 Haeba ho na le tšenyo e ka holim'a sefahleho sa flange mahlakoreng ka bobeli a 'mele, e tlameha ho sebetsa machining ho tsamaisana le tlhokahalo e tloaelehileng.

4.5 Mahlakore ka bobeli a khokahanyo ea RJ ea 'mele, haeba a sitoa ho lumellana le tlhokahalo e tloaelehileng ka mor'a ho lokisoa, a tlameha ho chesetsoa.

4.6 Ho fetola likarolo tsa ho roala

Ho roala likarolo ho kenyelletsa gasket, ho paka, O-ring joalo-joalo Lokisetsa ho apara likarolo ho latela litlhoko tsa tlhokomelo le ho etsa tlaleho.

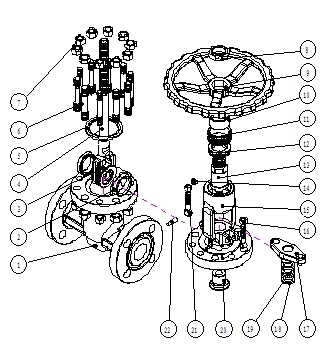

5. Kopanya le ho kenya

Litokisetso tsa 5.1: Lokisetsa likarolo tse lokisoang, gasket, ho paka, lisebelisoa tsa ho kenya.Beha likarolo tsohle ka tatellano;u se ke ua robala fatše.

5.2 Tlhahlobo ea ho hloekisa: Hloekisa likarolo tse ling (sefase, setiiso, kutu, linate, 'mele, bonnet, joko joalo-joalo) ka Kerosene, peterole kapa ntho ea ho hloekisa.Etsa bonnete ba hore ha ho na mafura le mafome.

5.3 Kemiso:

Qalong, hlahloba indentation ea stem le ho tiisa sefahleho sa heke ho tiisa boemo ba ho kopanya;

Hlakola, hlakola 'mele, bonnet, heke, ho tiisa sefahleho hore se lule se hloekile, Kenya likarolo tse ling ka tatellano 'me u tiise liboutu ka mokhoa o lekanang.

Nako ea poso: May-19-2022